Computer Numerical Control (CNC), a form of machining, has revolutionized engineering and manufacturing in the last few decades. In integrating digital technology and traditional machining processes, CNC machining has emerged as the most popular method of making high-precision parts and pieces in a variety of industries. This article will explore the mechanics and benefits and numerous applications of CNC machining to highlight its impact on modern engineering.

The Mechanics of CNC Machining

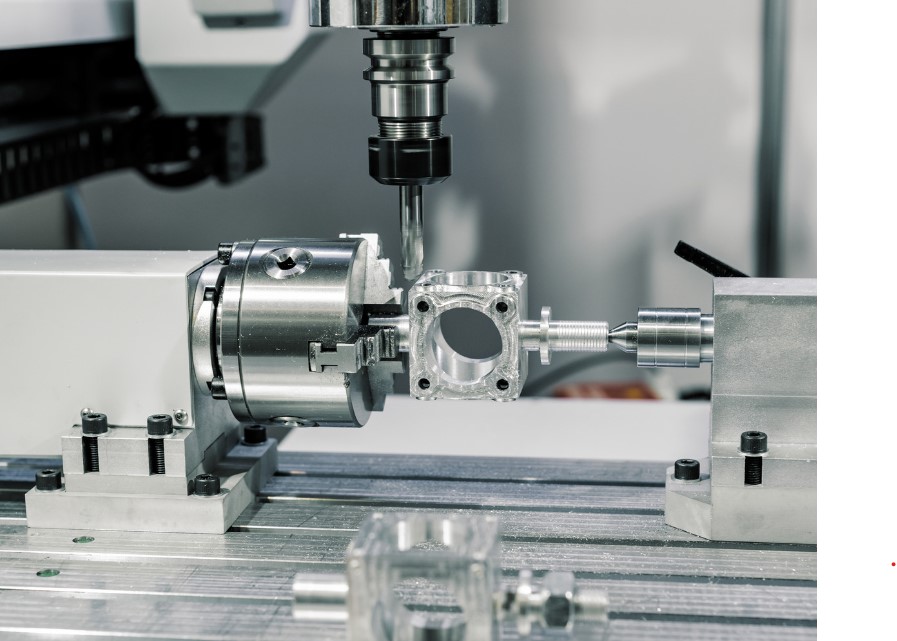

CNC machining is an subtractive manufacturing technique by which it is able to remove the material from a solid block or piece of workpiece to make the shape you want. The process is controlled by computer programs that controls the movements of the machine. The code created for CNC machines differs based on the specific model of machine as well as the complexity of the part being produced. The fundamental concept is the same, however: A high-speed cutter accurately sculpts material to create the final product.

The accuracy of CNC manufacturing is among the most important advantages. Digitalization can ensure extremely precise and reliable production. This helps reduce errors made by humans, and also ensures consistency between batches. This level is critical in the fields of aerospace, medical devices and manufacturing for automobiles, where slight deviations can have serious consequences.

Digital Computers and their role in CNC Machine Operations

Digital technology is the foundation of CNC machining’s efficiency and accuracy. CNC machines operate using specially designed software that controls every step of the manufacturing process. This software converts computer-aided design (CAD) models into a series of precise instructions, which the CNC machine then follows to create the part. The instructions set everything from direction and speed to depth and angle for every cut.

In industrial facilities of larger size, computers can be connected directly to CNC machines. This allows for seamless communication and control. This integration allows real-time adjustments and monitoring to ensure optimal performance, as well as reducing the amount of downtime. Automation of CNC machineries also permits continuous operation, significantly increasing productivity while reducing lead times.

The Advantages of CNC Machining

CNC machining comes with numerous benefits over traditional manufacturing methods. Its ability to create intricate and complex parts that are precise is one of the most significant benefits. CNC machining’s accuracy eliminates the need to perform manual adjustments, or to Rework. It also reduces waste and increases efficiency. CNC machines are also able to work in a continuous manner. This makes them perfect for large-scale production runs.

CNC Machining also has a benefit it’s flexibility. The CNC machine can be used to produce a wide variety of parts simply by changing the software. CNC machines can be utilized for mass production as well as prototyping due to its adaptability.

The automated process of CNC processing also enhances the safety in the workplace. The chance of injuries and accidents is decreased by reduction of manual intervention. In addition, the high-quality of CNC-machined products improves quality and reliability, adding to the satisfaction of the customer and enhancing the reputation of the brand.

Industries Benefitting from CNC Machining Services

CNC machining is utilized in a myriad of industries, each benefiting from its accuracy, efficiency and flexibility. CNC machines in the aerospace industry produce components that have to meet high standards for safety and performance. CNC machines are used in the medical device sector for the production of implants and surgical instruments where precision is the most important factor.

CNC machining is used in the automobile industry to create parts for engines, transmissions, and intricate exteriors and interiors. In the same way, the electronics industry is benefited by CNC machine’s capability to create tiny, intricate parts for consumer electronics and communication devices. Art and jewelry industries make use of CNC technology for intricate designs and custom pieces.

The future of CNC Machining

CNC machining capabilities are expected to increase as technology advances. Multi-axis CNC machining as well as additive manufacturing integration will continue to push the limits of CNC technology. Additionally, machine learning and AI will enhance CNC machine efficiency.

CNC machining is an extremely powerful tool that has impacted engineering and manufacturing in the present. It has unbeatable accuracy, flexibility, and effectiveness. Its capability to make complex parts with a high degree of accuracy makes it an indispensable instrument across a range of industries. As technology evolves, CNC machining will undoubtedly continue to play a crucial part in determining manufacturing’s future.