Spindles are vital in the world of advanced manufacturing in which accuracy, reliability and speed are not negotiable. Whether it’s carving aerospace-grade alloys or fine-tuning high-tolerance components for medical devices the machining spindle will be the hidden force behind precision, speed and the utmost consistency.

The forefront of this specialized industry are top spindle producers like POSA Machinery which are revolutionizing what quality and durability should look like in the machining environment of industrial manufacturing.

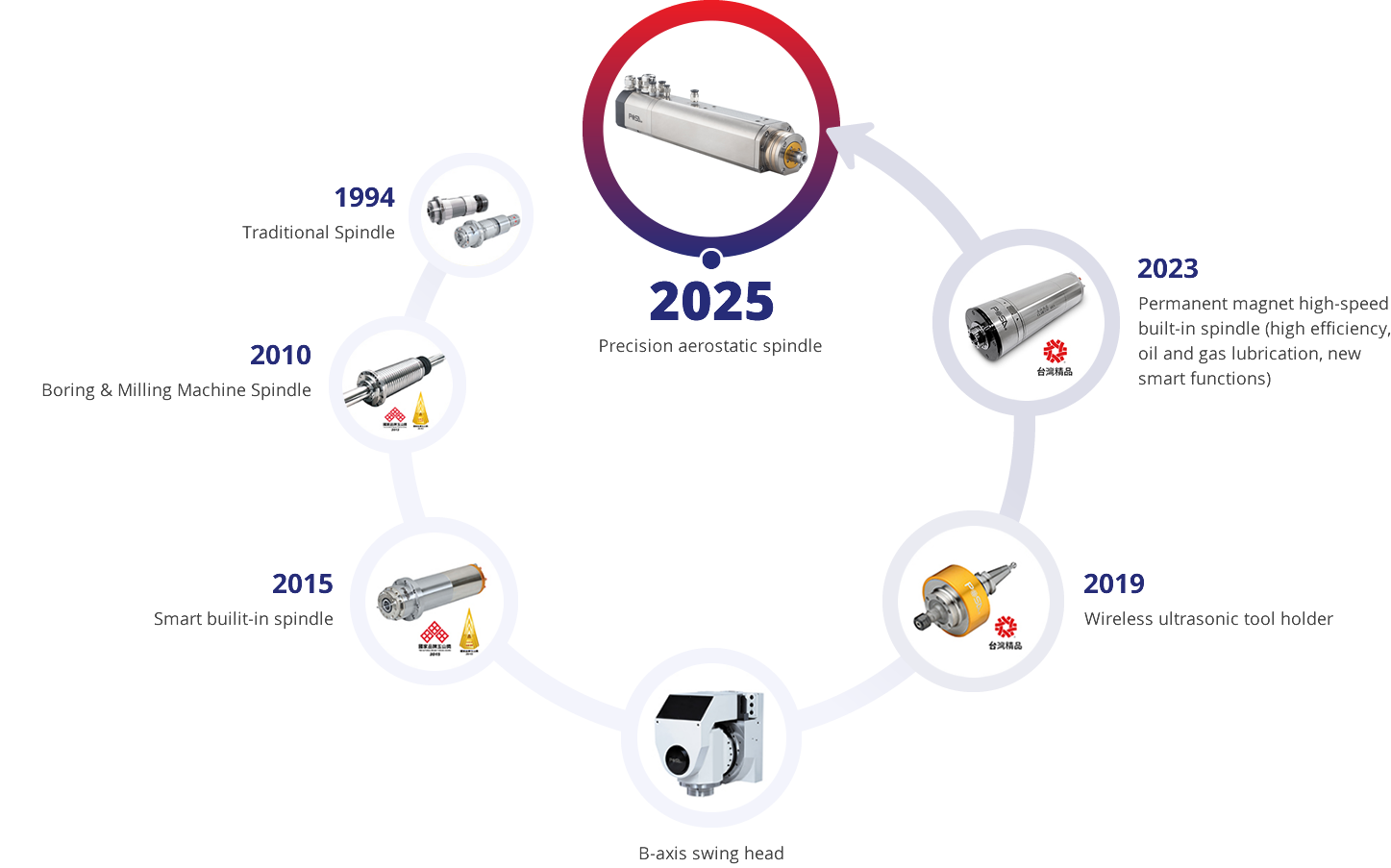

Image credit: posa-spindle.com

The reason the Spindle Is the Heart of the Machine

The spindle is the core of all CNC machines. Imagine the spindle as the center of a CNC lathe or machining center it controls the cutting tool with astonishing precision in stability, stability, and torque. Misaligned or poorly-made spindles can cause malfunctioning components, but they also can cause damage to the machinery. This will reduce the useful life of the equipment and interrupt the production cycle.

This is where precision spindle technology can make all the difference. Precision spindles, as opposed to conventional parts, are developed, checked and calibrated with great care to meet the needs of extreme and high-demand conditions.

POSA Machine is More than a Spindle Maker

POSA Machine is a pioneer in spindle production for years. While many spindle manufacturers claim to have high precision however they are not equipped with the knowledge and expertise in engineering that POSA has acquired over the years. It is known for its rigorous in-house testing protocols and commitment to the highest quality standards in the world, POSA does not just produce spindles they create solutions designed to meet the varied requirements of the modern industry.

POSA spindles are used in a variety of machines, ranging from vertical and horizontal machining centres to tool grinding machines. The spindles are protected by a thorough R&D procedure that focuses on not just functionality but also durability over the long term, vibration control and thermal stabilty.

The Evolution of the CNC Lathe Spindle

The CNC lathe spindle has seen remarkable innovation in recent years. Spindles are no longer just rotating axes. They now integrate sensors with cooling mechanisms, as well as intelligent balance mechanisms. POSA CNC lathe spindles allow the machinists with flexibility when handling hard and soft metals without sacrificing accuracy. With their cutting-edge ceramic bearings as well as quality construction, these spindles keep tight tolerances even over long runs. This type of reliability leads to improved quality of the part as well as reduced downtime and improved tolerances.

Customized Machining Spindles for Machining that Meet the Real-World Demands

There’s no such thing as a one-size-fits-all spindle for machining, particularly in the fields of aerospace, automotive, as well as die & mold manufacturing. POSA knows that every application requires specific specifications. It doesn’t matter if it’s spindle speed or load capacity, or environmental resistance, POSA can meet them. This is why they provide customizable spindle configurations built around individual client needs. POSA is able to provide the engineering support and flexibility that modern-day manufacturers are looking for, whether that’s developing a vertical milling machine or integrating a spindle with higher frequency into a compact machine.

More Than Machines: A Promise to Craftsmanship

POSA isn’t just about spindles, but also the philosophy that guides them. The company’s philosophy is a blend of skill and ingenuity. The design engineers collaborate with clients to learn about their needs, to listen to their needs and constantly enhance the products they provide. When machine uptime and repeatability are crucial to a production line’s success picking the right spindle partners is crucial.

Final Thoughts

The future of manufacturing rests not only on machines that are faster but additionally on the components that are more intelligent and reliable. POSA Machinery is a shining example of the positive results that can be achieved by spindle makers who blend technological expertise and a strong commitment to customer service. Whether you need a high-performance CNC lathe spindle, a high-performance grinding spindle or a precision-tuned spindle, choosing the right spindle isn’t merely a matter of preference, it’s a choice that will shape the entire downstream.